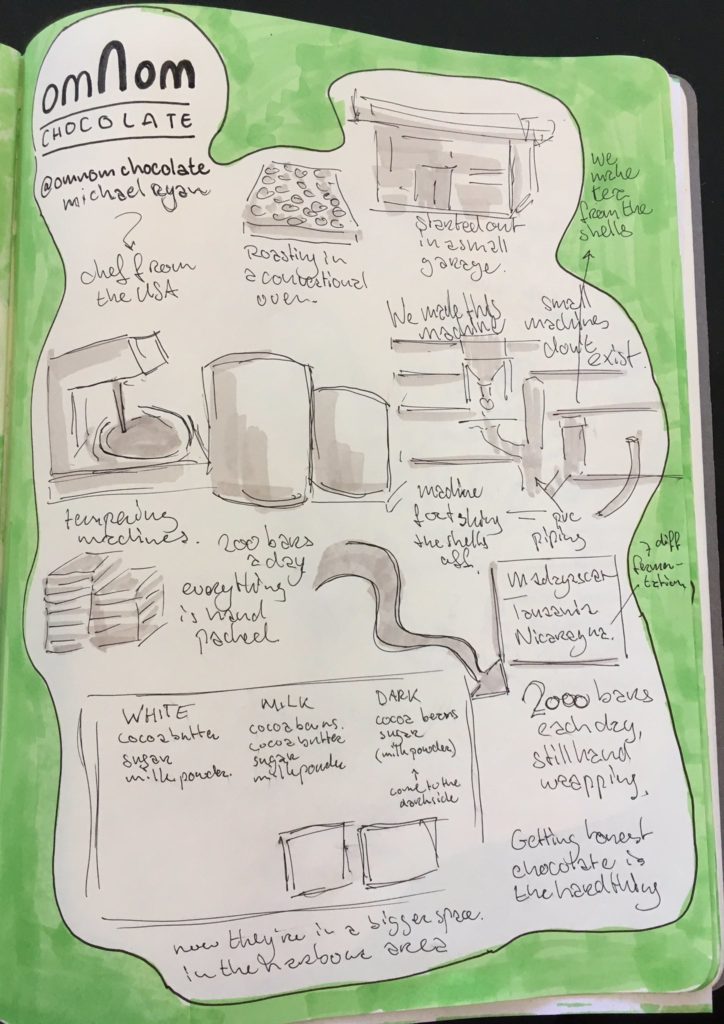

Michael from Omnom Chocoolate walked us through the history of the company. From how it all started in an old petrol station to moving to a new factory and growing the business. He gives an overview of the different chocolate types: White, Milk and Dark and what those categories mean. He also explains the difference between how big companies procure and treat their beans compared to how smaller, artisan companies do it. Big companies mix origins, over-roast and dilute along with mixing other products into their chocolate for a bland consistent flavour. Omnom source their beans from one of 3 origins. They are all traceable and are ethical.

As he got to know these materials more deeply, he began to understand the differences from the three origins. Madagascar beans comes from a single place: a single estate, from a single guy. Tanzania beans come from over 2,000 different farms all brought together to a single place to be processed. Nicaragua created a new method with 4 different ways to ferment the beans giving four distinct flavours to choose from. Each of these methods have pros and cons which affect the taste and flavour. Knowing what each is best at makes for interesting experiments.

Even in the strange world of chocolate, Omnom is pushing the boundaries. This is one of the reasons Michael made the jump to Iceland to work for them. His favourite bar (at the time of recording) and ours too (at the time of recording) was their coffee bar. The normal thing companies do is to add hints of coffee flavour to a dark, bitter chocolate. We were horrified to learn Omnom’s approach. The took white chocolate and added so much coffee the bar looks much more like a milk chocolate. You really do get a nice caffeine hit off of eating one!

Because…

Omnom is a local bean to bar chocolate company doing some weird and experimental products. We are big fans. They offer a “bean school” at their factory. We’ve done it. During which, they describe all the parts of a cocoa bean and the process to get that bean into chocolate. Then you get a small factory tour and see how they press the bars, wrap them, temper the chocolate and even their experiments workbench.

The thing that got us most interested is the part of their process where they identify waste and experimenting with it to turn it into new products. The cocoa bean husk still has lots of flavour. In most places, this is a waste, by-product from the goal of getting at the nibs. Omnom have been experimenting with cold brewing these husks and creating tea-like drinks. The husks have also been used in beer brewing and even as compose for top soil. Doing more with what we assume is waste can be a valuable resource for the business and is certainly overlooked in a digital context.

With their deep knowledge of the material and how it is best used to create a unique tasting experiences, how the packaging makes it stand out and how to never let anything be wasted, we wanted a presentation by Omnom to prime the minds of our attendees about their own projects and products.

Omnom ➞ Web

Long ago, we heard the origin story about SMS. When cellular towers were setup, the needed to communicate with each other. Probably for some load balancing and locating of cell phones. A brilliant engineer thought about those waste packets going between towers and wondered if it was possible to squeeze a short message in there? It turns out you could and that waste became a multi-billion dollar industry!

We don’t have an answer, but always wonder if there are opportunities on the Web to look for ‘waste’ and turn it into something valuable? Some services were using idle screen saver time to run tasks like SETI@Home to look for extraterrestrial life or Folding@Home to help look for molecules to cure cancers. There were others which searched for prime numbers. These days it is probably cryptocurrency that is sneaking in and using any space CPU/GPU downtime.

Omnom, without a doubt, has a mastery of their materials. To explore new flavours and origins the way they do only happens when you have a subtle understanding of how far you can push or pull different aspects of the material. It reminds me the old days of Flash when you visited a website and it wasn’t like anything you’ve seen before. (Granted the visual experience was amazing, but the usability – well, that’s another discussion) People were experimenting and finding out worked, what didn’t what could be reused and what was a one-off. That only happens when you have the time to experiment, understand and know your materials well.

There isn’t equipment for small scale chocolate production, so there is a lot of DIY and inventiveness getting started. The Web is great in that you don’t have to be a big giant company to publish, you can do it with some basic knowledge of HTML and even that isn’t always a requirement. We’re still in the early days of the Web and the DIY spirit is strong. From various CMSes, to layouts, to build tools, everything is still wide-open for experimenting.

Waste is also an underlying theme that we think a lot about. There was a quote about the early computer days of point-n-click GUI interfaces versus Command Lines. The only unix folks went on and on about command lines and how they were faster, more efficient and required little screen refreshing. The GUI folks didn’t listen. They were told to ‘be wasteful’ because what was computationally expensive today, would be cheap tomorrow, according to Moore’s Law. There is a limit to being wasteful, but we want to explore how, if it is possible, that we can turn that waste into a valuable product in its own right.

You can view all the video recordings and subscribe to the Material podcast on the Material Archive site.